The excellent characteristics of PIAD cast parts allow a variety of different applications in numerous industries, just to name a few as examples: electrical industry; mechanical engineering; instrumentation; textile machinery; printing machines; packaging equipment; locks & fittings; and medical applications.

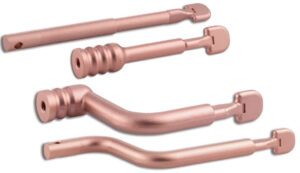

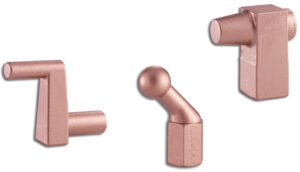

PIAD cast parts can weigh from a few grams up to 35 kilograms, with dimensions between 10mm and 500mm.

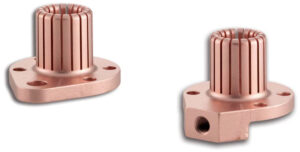

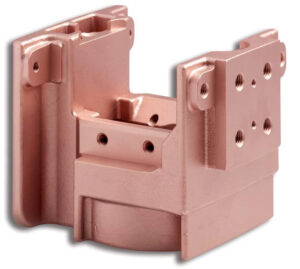

Copper and its alloys are well known for being colourful and non-ferrous, and used for electrical parts like armatures. The many other positive characteristics of parts made from these materials with the permanent mould casting method are not always well known by designers and decision-makers. Fortunately, however, this is changing as the materials and the permanent mould casting method gain more and more awareness in many industries. The number of well-known companies using engineering parts made with the permanent mould casting method continues to rise.

Energy

Due to the combination of innovation and high quality, customers of PIAD have crucial advantages over their competitors.

One example is the development by PIAD of the smelting and casting technology for pure copper. This method guarantees the high conductivity of the cast parts so much so that it is widely used in medium voltage and high voltage applications. This is important, because in many cases just one cast part can be fundamental to the operation of complex, technical equipment, such as the contacts in high-current circuit breakers.

The logical consequence is that PIAD permanent mould casting parts made of pure or low-alloy copper are in many cases a worldwide standard in energy distribution plants and switchgear.

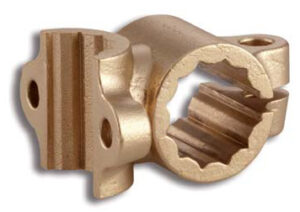

Mechanical

At PIAD, all aspects of a new design – consultation, development, mould design & construction, and production are all under one roof. This results in an advantage for our customers, they get efficient, innovative solutions which result in competitive and technical advantage.

For example, PIAD cast parts ensure printing machines can run at maximum speed without any loss of quality. Whether it is for the printing process, the paper feed or the paper transport; thanks to the wide range of materials and strong process control, PIAD cast parts are inherently reliable, which is so important for mechanical engineering components and companies.

This is also valid for many other mechanical applications, including packaging and textile systems. High precision, durability and innovation creating competitive advantages in the global market.

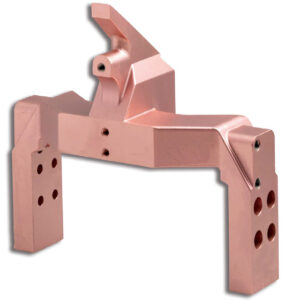

Transportation

Smooth operating conditions are crucial for safety conscious transport applications.

For instance, PIAD precision cast parts made of high strength and corrosion resistant aluminium bronze help to ensure the failsafe functioning of brakes on high speed trains. The individual components made of well-engineered materials guarantee a simultaneous activation of the mechanical and electronic emergency braking systems.

In addition, special door systems which need to operating smoothly and continuously under extreme stress are based upon mounting elements and levers from PIAD.

These are just two examples where PIAD stands for reliability and safety on the highest technical level worldwide.

Medical

The constant advances in medical engineering drive the need for parts with not only the highest quality and precision, but also the antibacterial characteristics of copper alloys. It is no surprise, therefore, that PIAD is a leading supplier of cast parts for medical engineering.

Thanks to continuous development, the achievements at PIAD have led to many improvement in this industry. One example is that x-ray machines are now more mobile. Additionally PIAD castings find applications in medical engineering where the quality has to be maintained but the economic efficiency can be optimised.

Precision cast parts made by PIAD are not just used for innovation in energy, mechanical, transportation or medical engineering – there are many other applications where PIAD parts are used with great success.

Often a change of material or method is a chance for improvement. You will see that the way of innovation can lead to changes in other aspects. On this path you will find solutions you never thought of before, more environmentally friendly and more cost-effective.