Management

“The knowledge and expertise of our workers about alloy techniques and our whole process chain of permanent mould casting is the most valuable asset of the company. If this know-how gets structured and combined with innovation and modern management concepts the company will create an advantage over our competition and thus significant benefits for our customers.“

Michael Breuckmann

Our corporate ambition is to implement and apply modern industry standards for the permanent mould casting. Key elements being delivery, reliability and flexibility.

By combining the market leading experience with high pressure die casting in high temperatures at Breuckmann and the technological capability of PIAD with permanent mould casting, the two most important permanent mould methods for copper and copper alloys are now together in one company. The result is that the Breuckmann Group is the largest provider of cast parts to customer drawings from copper and copper alloys. This means we are now able to individually identify the most cost-effective method for every single customer request.

History

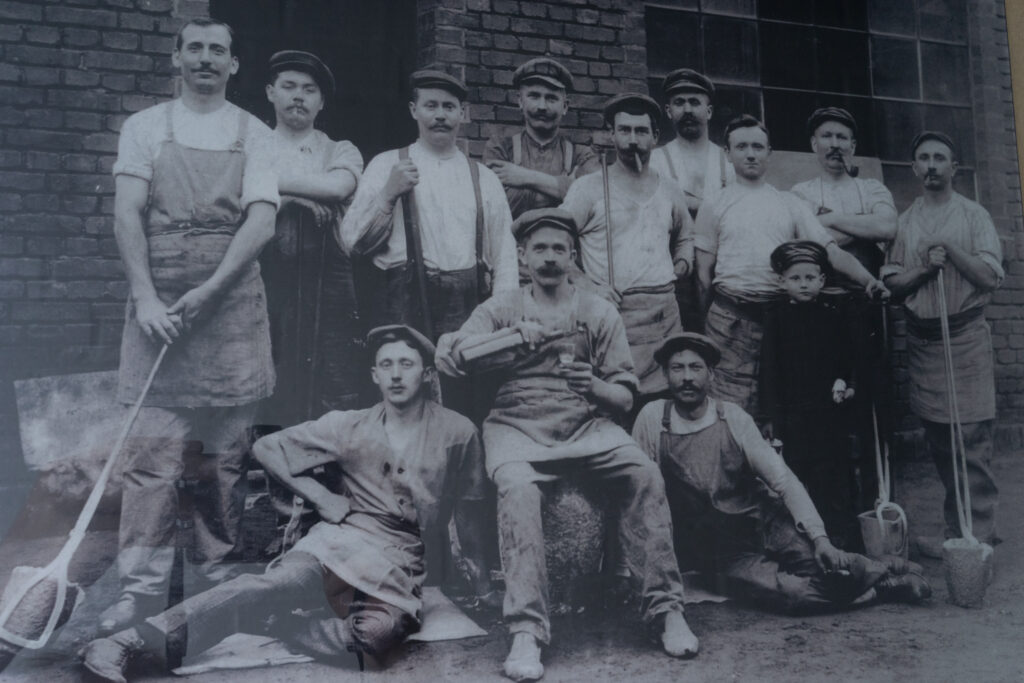

On May 1st 1900, Carl Adey and Carl Piel founded a metal foundry in Solingen, Germany. The order of the two names for the company name was decided by drawing lots, resulting in the name Piel & Adey (PIAD).

The Founders effort and persistence ensured the establishment of a company with a solid base. Their inventive genius and readiness to assume risks helped them achieve success and important patents. These patents were the foundation stone for the era of copper casting with the permanent mould casting method. The casting of copper and copper alloys in tilting or “tipping” casting moulds was invented by Piel & Adey. Since then this method has become known as the PIAD-tip-casting-method or chill casting.

When Carl Piel 90 was years old, he still went to work on a daily base, always eager to learn and full of ideas for the company. From his seventies onwards he used to say: “Don’t be cross with me, I would like to know today, if this works, because tomorrow I could be dead.”

The company philosophy is that: Nothing has to stay the way it is, just because it always has been like it. There is always a need to look for better working methods to improve work and economic efficiency, and to make it easier for the workers, especially for the caster. This basic thought runs like a thread throughout the company’s history from its beginnings to to the present day.

The first patent was granted on September 17th 1912 and many others were about to follow. Here are a small selection:

Patent no. 553551: Method and mould for the production of cast parts made of metals with a high melting point, especially for copper alloys.

Patent no. 674711: Method for the production of cast parts (near net shape) made of copper alloys in a continuous operation with metal moulds.

Patent no. 480900: Method for the production of metal parts made of difficult smeltable alloys with a content of copper above 50 % by a casting with a permanent mould.

Patent no. 547969: Method for the production of sharply formed cast parts made of difficult smeltable metals in casting moulds.

Patent no. 676438: Method for covering the inside of metal moulds by dip moulding.

Patent no. 748017: Multi-part mould and core for the production of casting parts made of non-ferrous heavy metals.

Patent no. 738996: Method for covering the inside of metal moulds with insulating materials.

Patent no. 892820: Method and apparatus for casting in moulds, especially for permanent mould casting. An upstreaming casting method by pushing the liquid metal in the mould with a replacement body.

In subsequent years the company continued to expand to other locations in Buchen and Spremberg, expanding the process capability to include investment casting.

After many years, the complexity of the different processes and casting methods in several locations in the emerging global market became unsustainable.

In July 2020 the Breuckmann Group acquired PIAD.

In the course of this takeover, the company refocused on its core competence (permanent mould casting) and operates the entire production from the main location in Heiligenhaus.

Im Juli 2020 dann erfolgte die Übernahme durch die Breuckmann Gruppe.

Im Zuge dieser Übernahme hat man sich wieder auf seine Kernkompetenz (Kokillenguss) fokussiert und betreibt die komplette Fertigung vom Gründungsstandort in Solingen aus.